Infrastructure Foundry Comprising of Plant 1 & 4

MELTING

With three solid-state thyristor controlled, medium frequency induction furnaces, with a

combined annual melting capacity of 13000 MTs and can produce single piece casting

weight upto 2.5MTs, Vijay Technnocrats offers greater process flexibility and highly

consistent quality products.

MOULDING FACILITY

Our state of the art equipment’s for Sand Mixing, Mould Making & Material Handling Systems and Sand Reclamation are second to none. We manufacture casting using the following processes.

- Green Sand Moulding –We have Installed 24Tons/Hr capacity sand plant with Mould Handing System (MHS) & PLC computing device as a model plant on turnkey basis to facilitate two ARPA-450 Moulding lines with flask size of 520 mm x 520 mm & 650 mm x 650 mm with casting weight up to 45 kg (single piece) can be produced.

- Cold Box process is established to manufacture critical cores with better productivity.

- No-bake Moulding - We have installed continuous mixer from WES Australia in both Plant 1 & 4 of 10 mt/hr capacity with compaction table and sand plant equipped with fluidized bed cooler classifier which can reclaim the foundry sand. We can produce moulds of size 3 m x 3 m x 1.2m.

- Shell Molding - being used for small castings for up to 20 kgs.

Pattern Shop & Development Department

Our in-house pattern shop has facility for Mounting. For preserving vast number of

patterns, we have implemented vertical storage concept for unique pattern storing &

handling system with library concept which also helps in better identification &

quick

retrievability. It is fully staffed with skilled craftsmen to maintain the integrity of

the pattern. The development department plays a crucial role in:

- Using Autocast simulation software to troubleshoot prior to production

- Total design of tooling and methoding

- Product improvement

- Quick prototyping

- Feasibility study

- Cost savings

All pattern equipment is verified for the accuracy of dimensions before releasing to production.

CASTING FINISHING

Our centralized cleaning and finishing facility will ensure quickly and thoroughly processed, Irrespective of size. We use Hanger Type Shot Blast Machine in Plant 1 & 4 with capacity of up to 1 MT & 0.5 MT respectively.

We utilize highly efficient, Compact and sound protected nozzle shot blast system for cleaning intricate internal cavities in the castings to meet Millipore test requirements of customers.

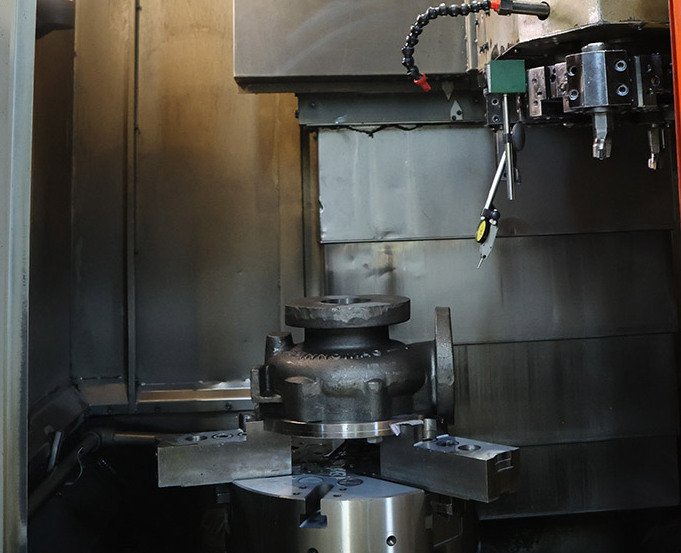

Machining

Machining

Machining

Our full-fledged Machine Shop provides a range of machining functions including

turning, milling, drilling and threading. This CNC Division is equipped with some of

the largest and most modern machining equipment and is housed in a new 35,000 sq/ft

facility. We can achieve tolerance of 12 micron on finished components and machine

castings of hardness up to 60 HRC.