25 YEARS OF EMINENCE

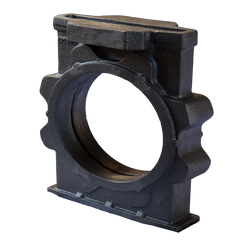

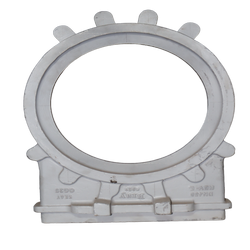

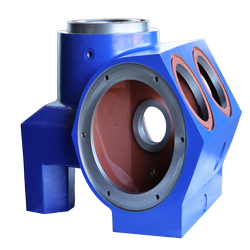

Vijay Technnocrats Private Limited, one of the proud members of Shanthala Group of Industries was established in the year 1999 by a team of well qualified, experienced Metallurgists and Mechanical Engineers to manufacture Iron castings and components. Vijay Technnocrats draw on the expertise of skilled craftsmen, a highly trained staff, in-house pattern shop, laboratory to meet NABL standards, Heat Treatment & Painting facility, cutting edge computer technologies and state-of-the-art machine shop to exceed the expectations of our esteemed customers.

We have an exponential growth in our export customers portfolio since 2009 and we are proud of supplying to following Countries globally to multiple sites in USA, Australia, UK, Canada, Germany, Spain, France, Belgium, Hungary, China, UAE, Singapore, Saudi Arabia, Malaysia, Japan, Romania, Mexico & Thailand.

“ Started Export Business in the Year 2009. Export of Machined Components of all grades meeting National & International standards which comprises of Ready To Assemble & Ready To Use conditions. Our Main Focus is the supply of Quality Parts On-time. Presently 25% of our sales go to Export Business ”

Our Services

Infrastructure

Awards & Recognitions

2023 - Supply chain Excellence Award

M/s WEIR Minerals India Private Limited

2017 - Best Supplier Product Quality

M/s BUHLER India Private Limited

2012 - Best Supplier Award

M/s WEIR Minerals India Private Limited

Certifications

ISO 9001 : 2015

Quality Management System

ISO 14001 : 2015

Environment Management System

ISO 45001-2018

Occupational Health and Safety Management System

RoHS & REACH Compliant

- Deals with the regulations that were created to improve the environment and protect human health. REACH addresses the risks associated with chemicals and promotes alternative methods for the hazard assessment of substances.

Green Energy

- Initiative provides real benefits for the environment by way of mitigate climate changeand conserve resources since the power comes from natural resources such as sunlight, wind and water. They're essential for building a more sustainable, resilient and healthier future. Green practices promote planet-friendly habits and reduce environmental impact.

- In view of the above we have installed Solar Power Plant in Unit 2 Machine Shop (Generates 1300 Units/Day which is 70% of the present consumption) & Unit 4 Foundry (Generates 1100 Units/Day). Also, we are planning for ISO50001 Certification by end of 2024 for establishing, managing and improving energy consumption and efficiency